Pronterface

General information¶

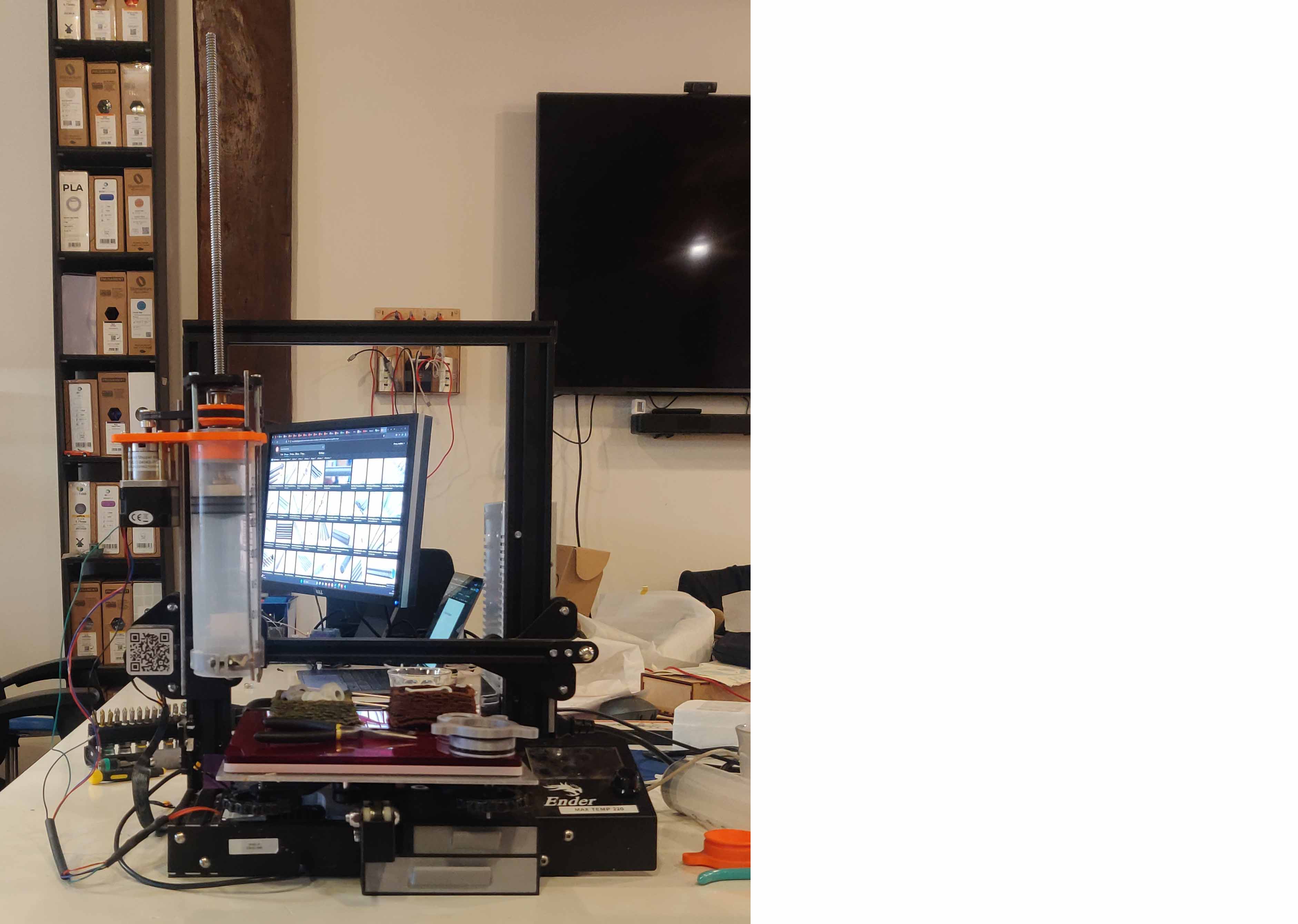

As of 2023 this printer has been changed into a dedicated biomaterial 3D printer. On this page you can read more about biomaterials and the setup of the software to use the printer. On the How to Use page you can find more information on how to use the printer once you have installed the software and have prepared the recipes for the biomaterials.

Biofabricated material¶

To work with the biomaterial 3D printer, you have to prepare a biomaterial paste as a material. A biomaterial is a term used to indicate materials that have non-specific biological association. If you start printing with biomaterial, you will be making a biofabricated material. Biofabricated materials are produced by living cells (e.g. mammalian) and microorganisms such as bacteria, yeast and mycelium. The material exists out of biofabricated ingredients (living cells and microorganisms such as bacteria, protein, etc.) that are afterward mechanically or chemically processed in order to make a macroscale material structure. This processing can be done through yarn spinning, 3d printing, laser cutting, and many more (Biofabricate and Fashion for Good, 2020). To understand the relation of biomaterials and biofabricated materials better, Fashion for Good and Biofabricate (2020) have created a chart to show the term biomaterials and everything that it includes.

To make a paste for the biomaterial 3D printer, you need to start with what you would like to print. If you want to make a 3D model with some height, you need a thick paste. If you want to print more laced patterns, you can use a more liquid paste. I recommend trying out your material first by putting it in a plastic bag and cutting off a little corner. Now you can see how the paste you make behaves when pushing it out an opening. Try to create something similar that you want the 3D printer to create and see whether that would work with the paste you have made. Let the test dry and see the outcome. If the outcome of the test meets your wishes, start moving towards the 3D printer. When you start making the paste for the 3D printer, a paste of 250/300 ml will be enough to start testing.

After deciding what to print, you also need to think about the size of the nozzle that you want to print with. The 3D printer has 5 different sizes: 6mm, 5mm, 4mm, 3mm and 2mm thickness. Depending on the size of the nozzle, your material needs to adapt. The thicker your material, the bigger nozzle you need to use.

For recipes on biomaterials, have a look at:

Pronterface¶

To work with the biomaterial printer, you have to download Pronterface. Pronterface is a free, open-source software, licensed under the GNU General Public License, version 3. The software allows you to send code directly to the printer. This means that, whereas with a normal 3D printer you would slice your 3D object and let a programm such as Ultimaker Cura or Prusa Slicer create a .gcode file to put on a usb/sd card which then in turn gets inserted in the printer, you can now copy paste this .gcode in the Pronterface software and let the software directly send the code to the printer. This is convenient since it will buy you time. Depending on your biomaterial, your settings of the printer are different. Think about how fast the head of the printer needs to move, how much pressure you need to put on the material to extrude, how high it needs to be calibrated from the bed to extrude the right amount of material, etc. When you are trying out a new biomaterial, your setting will be different. Directly changing this on Pronterface and sending that to the printer will buy you time. While using an usb or sd card in between will take much going back and forth between the laptop and the printer.

Steps Pronterface¶

To set up Pronterface and the printer correctly, please follow the steps below:

-

Open Pronterface. When you have Windows, this will automatically happen when clicking on it. When you have Mac, you need to right click and then click open. You will get a pop up menu where you have to allow Pronterface to run on your Mac, after that it can open. Double click on the programm will not do the trick when having Mac, it will then give a pop up menu that states that “The application “pronterface” can’t be opened”.

-

Now that you have Pronterface installed and it works on your laptop, close it again.

-

Give the 3D printer power and turn it on. Connect the 3D printer via usb cable to your laptop.

-

Check if the printer is connected to the computer. On windows you can do this by looking at the different usb inputs in your folders window. Now you know the name of the printer. On Macbook you can do this my moving to your terminal and write the code

ls /dev. Now terminal will give you a list of all the developers on your mac. Look for a name tty.usbmodem21201 (or something similar). If you can’t find it, disconnect the printer by taking out the usb from the laptop, give terminal the code again and see if there is one developer in the list that is now missing. If correct you can find one missing; that is the name of the 3D printer. -

When having the printer connected to the computer, open Pronterface again.

-

On the top left corner you can choose your port. Now choose the port of the correct name that you just found. In my case the name is

tty.usbmodem21201. Next to the port, you choose settings of @. These need to be115200. Now click connect. If correct, you can see on the right side of the screen a window that saysconnecting... printer is now online. -

Check whether Pronterface works on your laptop by moving the head of the printer 10 mm on the x or y axis (see images below for more info)

General codes with Pronterface.¶

- G1: The G1 command tells your printer to move in a straight line to the location that you specify.

- X, Y, Z: In pronterface you can use X, Y, or Z values to tell the printer what position to move to.

- E: The E value tells the printer how to move the extruder. The E value corresponds to the position of your filament spool, so if you move the E axis by 10mm, that would cause 10mm of your filament to be pushed out of the nozzle.

- F: You can use an F value to tell the printer what speed to use for the movement.

- If you want to learn more about coding with Pronterface, please visit this website.

Print bed¶

The print bed of the biomaterial printer is not like other 3D printer printbeds. It does not heat up like other beds always do since the biomaterial does not respond to heat like that. We’ve replaced the stock Ender board with the SKR Mini E3 V2.0 board. On top of that now lay 2 lasercutted vinyl boards: A white one that always needs to stay in place and 2 red ones, where you only need to use 1 of every time you print. This way you can print something and let this dry, while using the other board to print something new.

Filament extruder¶

The filament extruder of the biomaterial printer is also not like other 3D printer extruders. Like the print bed, it does not heat up to melt the biomaterial, but it pushes the biomaterial out of a tube that is connected to the printerhead. Depending on the biomaterial you use, you should change the nozzle on the extruder to different sizes. Keep into account that the paste you make needs to be very smooth. Little chunks can clog the extruder.

Filament roller guide¶

For the 3D printer I have used different sorts of recipes as filament. They were based on either sodium alginate or celulose powder. In my experience, to print with the biomaterial printer, you need a solid and thick paste if you want to create height. If you want to print more lace patterns, you can print with a more liquid paste.

Links¶

For links on different sorts of biomaterial recipes, have a look here or here